The Importance of Automation in Production

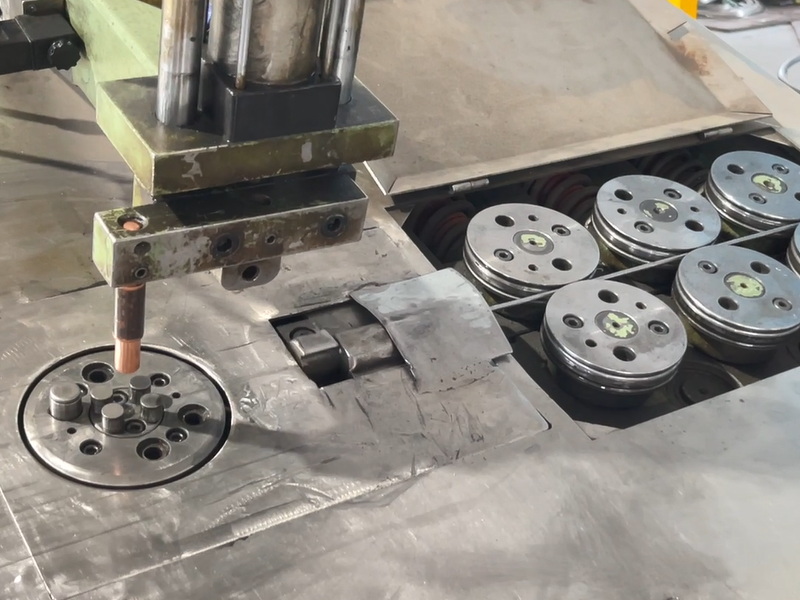

At one time, many of our home production industries were labour-intensive enterprises. The production area was dirty, there was no standardised process, the production efficiency was low, the yield rate was not high, the start-up rate was affected by the use of labour, the overall product cost was high and the competitiveness of the product was low. Particularly like the previous production of some metal fruit baskets, storage baskets, dish racks and other products, welding requires precise cuts and sizes, but manual operation often leads to poor precision and more inferior products.

Now many domestic industrial production enterprises are in the automation transformation, in fact, the application of these devices in the factory enterprise, in addition to the transformation and upgrading, the most prominent and most urgent an important significance, that is, can bring better revenue to the production enterprise, can help the production enterprise better to reduce costs.

Current trends and challenges in manufacturing automation

Given the inevitability of technological upgrades in recent years, many manufacturers have begun to explore ways to cope with the changing regulations in the run-up to the New Crown outbreak. However, since the New Crown pandemic, the adoption of automation has accelerated, with many looking to automation to keep employees safe while saving time and money. While the transition to automation may seem daunting at first, it doesn't actually require an in-depth understanding of coding - the main challenge is determining where to start.

Automatic bending machines

The introduction of automated machines is a very quick way for production companies to increase their productivity, as many production areas are now labour-intensive. But in the future, people will become less and less, the ageing will become more and more serious, so in the future, the production of enterprises may slowly start to develop from labour-intensive to become technology-intensive and talent-intensive. This is why there is a need for many automated tools to replace traditional manual labour.

Automated cutting machines

Automated machines, which can solve the shortage of manual labour. Three years into the epidemic, the values of Chinese workers have changed. Many workers have returned to the countryside and are reluctant to work in factories, resulting in a labour shortage. Although China is said to be a large population country, this ageing problem is actually now imminent. So there is a great need to replace traditional manual labour with some automated tools. It is clear that automated tools are indeed doing a good job in this respect, replacing manual labour and reducing labour costs on the one hand, and on the other hand, there is a huge increase and improvement in production efficiency.

The future of manufacturing automation

Looking to the future, many companies are beginning to introduce automation into their businesses, prioritising those segments that are relatively easy to implement, i.e. those processes that have a high potential for automation and low complexity. Automation upgrades in these areas can provide a high return on investment quickly, so more and more manufacturers will start to look to automation.

Metal home assembly line operations