LFGB Food Safety Testing for Powder Coated Products

Iron wire powder coating is a kind of surface treatment material widely used in home, construction and other fields. It has excellent anti-rust, anti-corrosion, wear-resistant, decorative properties, as well as environmental protection, safety and other characteristics.

Our iron wire powder coating products, such as Decorative Storage Baskets , etc., mainly consists of the following materials:

Iron wire: usually galvanized iron wire or stainless steel wire, with good conductivity and corrosion resistance.

Powder: mainly adopts polyester resin, epoxy resin and other high-performance resins, with good adhesion, abrasion resistance and weather resistance.

Additives: including stabilizers, leveling agents, matting agents, etc., used to improve the performance and appearance of products.

Solvent: used to adjust the viscosity and drying speed of the coating, generally using environmentally friendly solvents.

Second, the surface treatment process of iron wire powder coating products.

The surface treatment process of iron wire powder coating products mainly includes the following steps:

1. Pre-treatment: remove oil, rust, oxidized skin and other impurities on the surface of the wire to improve the adhesion of the coating and the substrate.

2. Coating: Coat the powder coating evenly on the pre-treated wire, generally using electrostatic spraying or fluidized bed spraying and other methods.

3. Curing: Put the coated products into a constant temperature and humidity environment for curing, so that the powder coating forms a solid coating.

4. Post-treatment: The cured coating is polished and cleaned to make the surface smooth and flawless.

5. Inspection: Performance and appearance inspection of the finished product to ensure that the product quality meets the requirements.

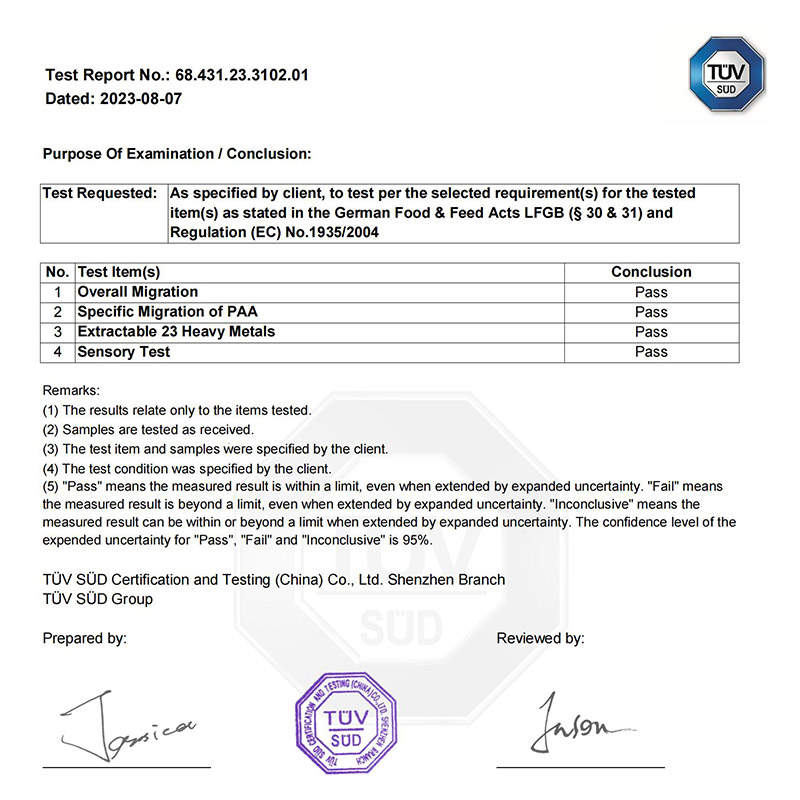

Third, the European requirements for powder spraying products LFGB test.

European powder spraying products (LFGB) test is a safety assessment for food contact materials, mainly used to detect whether the harmful substances in the coating exceed the standard.LFGB test requirements are as follows:

1. Testing scope: applicable to all materials that may come into contact with food, including metal, plastic, rubber, paper, etc.

2.Testing items: Mainly include testing of lead, cadmium, mercury, chromium, polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE) and other hazardous substances.

3. Limit standards: According to the relevant European regulations, strict limit standards are set for the above hazardous substances. For example, the content of lead shall not exceed 0.1mg/kg, and the content of cadmium shall not exceed 0.01mg/kg.

4. Test Methods: Adopting the test methods and standards specified by the EU, such as EN71-3, ASTM F963 and so on.

Fourth, our company successfully obtained the test passed the situation.

The wire spraying powder products produced by our company have successfully passed the LFGB test after strict screening of raw materials, production process control and quality inspection. The test results show that the content of lead, cadmium, mercury, chromium and other hazardous substances in our products are lower than the limited standards stipulated by the European Union, and meet the requirements of the European LFGB for food contact materials. This fully proves that our wire spraying products, especially Black Wire Storage Fruit Basket, have high safety and environmental protection, and can be safely applied in the food contact field.