How to Inspect the Powder Coating Finishing

Metal powder coating is a common surface treatment method that can enhance the corrosion resistance, wear resistance and decorative properties of metal materials of kitchen storage racks and bathroom racks. In the process of application, how to ensure the quality of powder coating becomes a very important issue, the following is the method of metal powder coating quality test.

1. Color standard determination

Color standard is the basis for the development of coating color specifications. According to the need, you can choose the international common color standard, such as RAL color standard. The color standard determination must be observed under sunlight or fluorescent light to avoid the light affecting the correctness of the color.

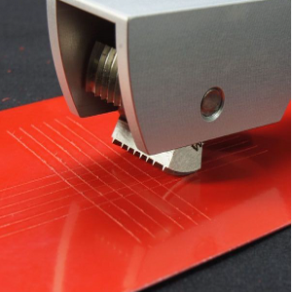

2. Coating adhesion test

The adhesion of a coating is one of the most important factors affecting its corrosion resistance and wear resistance. The coating adhesion test can be done by cross-hatching method, tie bar method, etc., where cross-hatching method is more commonly used. The method is to use a fine-tipped pencil to scratch two mutually perpendicular 10 cm-long lines on the powder coating, and then stick a small piece of adhesive tape with an area of 1 cm2 of backing paper at the intersection of the scribed lines, after which the tape is quickly torn off, observed by eye and examined by magnifying glass to see whether the coating appears to fall off or separate, and assessed the score.

3. Anti-oxidation salt spray test

Anti-oxidation salt spray test is to use salt water solution to simulate the damaging effect of marine, industrial and urban atmospheric environment on the anti-corrosion performance of the coating. When testing, the coating sample is placed under constant temperature and humidity, and sprayed onto the coating with 3% salt solution atomized, and the corrosion degree of the coating is detected after a period of time.

4. Coating thickness test

Coating thickness is one of the key parameters, which can be measured by magnetic induction. The method is to apply a magnetic substrate on the coating surface and then test it with a magnetic induction measuring instrument. This method can be used to measure different types of powder coated coatings such as metallic, non-metallic and composite coatings.

In summary, quality testing of metallic powder coated coatings needs to be performed based on a series of standards, test protocols and instrumentation to ensure that the coating meets specific needs and requirements in terms of color, adhesion, corrosion resistance.