Automatic Burning Machines Revolutionize Iron Household Product Manufacturing

In the field of producing iron wire metal storage baskets and kitchen organizers, bathroom shelves and other iron household products, the operation of new automatic burnishing machines has driven a significant shift in the production process. These machines have revolutionized the way our iron household products are produced, redefining the efficiency, precision and versatility of production.

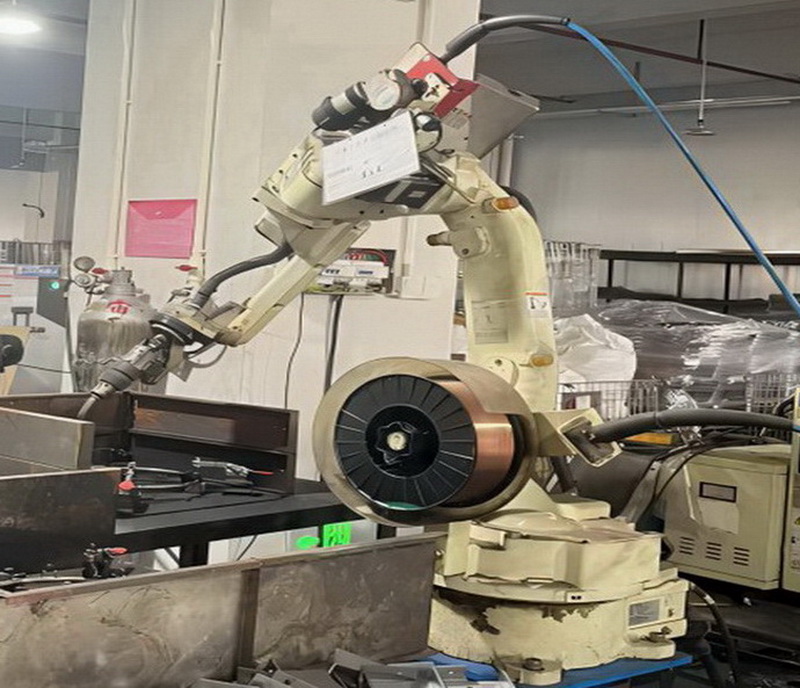

At the heart of this innovation is the robotic arm autoburner, a precision tool for robotic technology to accurately weld and shape iron materials with unparalleled accuracy and safety. This technology greatly simplifies the production process of iron household products and offers a variety of advantages that improve the quality and design of these products.

Welding, as one of the main processes for joining materials, has gone through several stages of development. From the initial forging and gas welding to the later arc welding and laser welding, the advancement of welding technology has boosted the productivity and reliability of various products. Especially in the manufacturing process of iron household products, welding is an indispensable and important part.

Although the traditional welding process meets the production needs to a certain extent, it also has many limitations. First, manual welding requires high skills of skilled workers and is easily limited by human resources. Secondly, the efficiency of manual welding is relatively low, the production cycle is long, and the welding quality is difficult to guarantee. In addition, traditional welding has a greater impact on the environment, generating fumes and noise that pose a threat to workers' health.

With the arrival of the industry 4.0 era, automated welding technology is gradually emerging. Automated welding can not only effectively solve the shortcomings of manual welding, but also improve the intelligent level of the production line. The new automatic welding equipment can realize precise welding control, ensure the stability of welding quality, and greatly improve the production efficiency.

Technical characteristics of the new automatic welding machine

The introduction of the new automatic welding machine, the integration of a number of advanced technologies, with the following significant features:

High-efficiency welding

The new welding machine adopts high-frequency arc welding technology, which is capable of melting and cooling in a short period of time, and the welding speed has been increased by more than 50%. The introduction of this technology has led to a significant increase in production efficiency and shortened the delivery cycle.

Precise control

The new welding machine is equipped with an advanced automatic adjustment system for welding parameters, which can automatically adjust the welding current and voltage according to different materials, thicknesses and welding positions to ensure the uniformity and strength of welding.

Intelligent Management

The welding machine is equipped with a built-in intelligent monitoring system, which can monitor the data in the welding process in real time and optimize the adjustment through data analysis. This system not only improves the stability of welding, but also records the welding process in real time, providing a basis for subsequent quality tracing.

Environmentally friendly design

The new welding machine is designed with full consideration of environmental protection factors, adopting a low-emission, high-energy-efficiency welding method, which reduces harmful gas and noise pollution in the production process and meets the environmental standards of modern industry.

Impact on the manufacturing process of iron household products

The introduction of the new automatic welding machine will have a far-reaching impact on the manufacturing process of iron household products, mainly reflected in the following aspects:

Improvement of product quality

The improvement of welding quality directly affects the service life and safety of products. The precise control and intelligent monitoring of the new welding machine can effectively reduce the rate of welding defects and improve the strength of welded joints, thus enhancing the overall quality of the final product.

Reduced Production Costs

The new welder can significantly reduce production costs by improving welding efficiency and reducing the defect rate. Although the initial investment is large, but in the long-term operation, the advantages of automatic welding equipment will gradually appear.

Faster Market Response

The new welding machine's efficient production capacity, so that enterprises can quickly respond to changes in market demand, shorten the development cycle of new products, improve market competitiveness.